Best way has become a sole agent for AIPU (Authorized distributor) for drilling fluid processing equipment in Egypt through authorization from AIPU Solids Control.

Shaanxi Aipu Solids Control Co., Ltd (AIPU Solids Control) is an ideal partner of drilling fluid processing equipment throughout the globe. AIPU Solids Control offers a complete range of specialist solutions, making use of current technology to provide clients with a range of competitive and efficient services. Oil & Gas Solids Control System Fracture Fluid Drainage Management System Drilling Waste Management System Oil Sludge Treatment HDD/Trenchless Mud System The main equipments: shale shaker, desander, desilter, mud cleaner, decanter centrifuge, cuttings dryer, centrifugal pump, degassers, mud agitator, mud tanks,etc Shale Shaker Screen

AIPU Factory

Global Exhibition

Certificates

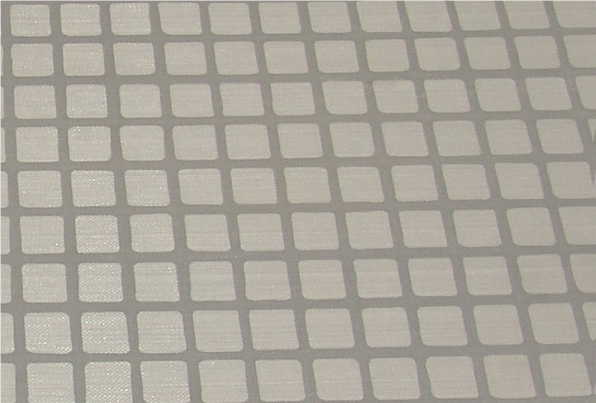

Aipu shaker screen

Aipu shaker screen Belongs to Shaanxi Aipu Solids Control Co., Ltd (Aipu solids control). We moved in Xi’an in 2013, however, we have been in solids control and shaker screen industry over 18 years. Our main staff even shares in over 20 years of screen manufacture experience. We always focus on providing right shaker screen for all makes and models of shaker over the globe. Aipu take quality to heart and continuously improve products under “custom-oriented” standard. High quality shaker screen will optimize solids control efficiency finally cut costs for whole well drilling. Aipu quality screen at economical cost is the best solution for you.

What can We do for you?

- Replacement shaker screen for almost makes and models

- Shaker screens repair plug

- Shaker screen clamping parts

Replacement screen panels available

FLC300 series shaker

FLC500 series shaker screen

Hyperpool shaker

48x30 series shaker screen

600 shaker screens

Poly-Web

ALS shaker screen

BEM-3 Shaker

BEM-6 series

MD series screen

MEERKAT shaker screen

MONGOOSE PRO,MONGOOSE PT shaker

SWECO 4x3 shaker

Cobra, King Cobra series shaker

LCM series shaker

LM shakers

VSM series shaker screen

4x3 shakers

4x5 shakers

ESS-48AG shaker

KDDX shaker

KDX shale shaker

KPT 28 shaker

KPT 26 shaker

Black thunder series shaker screen

2L, 20L series shaker

50, 50/500 shakers

DFTS shaker

Tri-Flo shaker

Even more and customization for you

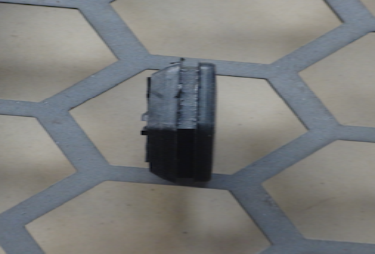

Shaker screens repair plug

According to different holes on screen panels the screen repair plugs can be rectangular, hexagonal shape, triangle, and square shape, etcetera. The appearance can be black color, white, red, or orange. Please find picture as reference

Shaker screens clamping parts

Shaker screens clamping parts vary significantly among different shaker screens also manufacturers. Including the fixing hook, wedge block, and so on

Replacement shaker screens from Aipu

Popular API size of replacement screen

| d100 separation µm | API Screen number |

|---|---|

| > 780.0 to 925.0 | API 20 |

| > 655.0 to 780.0 | API 25 |

| > 550.0 to 655.0 | API 30 |

| > 462.5 to 550.0 | API 35 |

| > 390.0 to 462.5 | API 40 |

| > 327.5 to 390.0 | API 45 |

| > 275.0 to 327.5 | API 50 |

| > 231.0 to 275.0 | API 60 |

| > 196.0 to 231.0 | API 70 |

| > 165.0 to 196.0 | API 80 |

| > 137.5 to 165.0 | API 100 |

| > 116.5 to 137.5 | API 120 |

| > 98.0 to 116.5 | API 140 |

| > 82.5 to 98.0 | API 170 |

| > 69.0 to 82.5 | API 200 |

| >58.0 to 69.0 | API 230 |

| > 49.0 to 58.0 | API 270 |

| > 41.5 to 49.0 | API 325 |

| > 35.0 to 41.5 | API 400 |

Why Aipu shaker screen?

- Professional manufacturer on shaker screen

- Excellent quality wire mesh and raw material

- Mesh size conform to API RP 13C standard

- High opening percentage

- Efficient filtration performance

- Quality painting after sand-blasting

- OEM/ODM service available

- Clients oriented improvement

- High appreciation from users

- Most reasonable price for cost-efficient solution

Aipu shaker screen available options

-

Hunter-MG Drilling Mud Shale Shaker

-

Specifications

| Model | Hunter MG3 | Hunter MG4 | Hunter-MGD |

|---|---|---|---|

| Handling Capacity | 110m3/h | 140m3/h | 140m3/h |

| Screen Area | 110m3/h | 140m3/h | 140m3/h |

| Screen Number | 3 sheets | 3 sheets | 4 sheets |

| Max. Vibration Strength | 7.0G | 7.5G | 6.0G-7.0G |

| Deck Angle | -1-+5° | -1-+5° | -1-+5° |

-

APZCQ Vacuum Degasser

-

Specifications

| Model | APZCQ240 | APZCQ270 | APZCQ300 | APZCQ360 |

|---|---|---|---|---|

| Treating capacity | 240m3/h | 270m3/h | 300m3/h | 360m3/h |

| Ratio | 1.68 | 1.68 | 1.68 | 1.72 |

| Efficiency | ≥ 95% | ≥ 95% | ≥ 95% | ≥ 95% |

| Motor | 15KW | 22KW | 30KW | 37KW |

| Pump motor | 2.2KW | 3KW | 4KW | 5.5KW |

| Speed | 860rpm | 870rpm | 876rpm | 880rpm |

-

Hunter Mud Cleaner

-

Specifications

| Model | Hunter120 | Hunter200 | Hunter240 | Hunter320 |

|---|---|---|---|---|

| Treating Capacity | 120m3/h | 200m3/h | 240m3/h | 320m3/h |

| Desilter Cone | 4"x8 | 4"x10 | 4"x12 | 4"x16 |

| Desander Cone | 10"x 1 | 10"x 2 | 10"x 2 | 10"x 3 |

| Working Pressure | 0.25~0.45 MPa | |||

| Separation Point | 15µm-74µm | |||

| Bottom Shaker | Hunter series | |||

| Vibration Mode | Optional | |||

| Motor Speed | 1500rpm/1800rpm | |||

| Remark | 4" Cones treating capacity is around 12-15m3/h, 8"Cones treating capacity is about 30-35m3/h,1O" Cone treating capacity is about 90-120m3/h. Whole capacity of mud cleaner can be adjusted per actual demand | |||

-

APCS Desander

-

Specifications

| Model | APCS60 | APCS120 | APCS240 | APCS360 |

|---|---|---|---|---|

| Max. Treating Capacity | 60m3/h | 90~120m3/h | 200~240m3/h | 320~360m3/h |

| Cones | 200x2(8"x2) | 250x1(10"x1) | 250x2(10"x2) | 250x3(1 0"x3) |

| Working Pressure | 0.25~0.45MPa | |||

| Separation Point | 44~74µm | |||

| Bottom Shaker | Single deck screen sized about 1 m2 driven by 0.4KW motor. Or customzied | |||

-

APCN Desilter

-

Specifications

| Model | APCN60 | APCN120 | APCN240 | APCN360 |

|---|---|---|---|---|

| Max.Treating Capacity | 60m3/h | 90~120m3/h | 200~240m3/h | 320~360m3/h |

| Cones | 100x4(4"x4) | 100x6(4"x6) | 100x12(4"x12) | 100x16(4"x16) |

| Working Pressure | 0.25~0.45MPa | |||

| Separation Point | 15~44µm | |||

| Bottom Shaker | Single deck screen sized about 1 m2 driven by 0.4KW motor.Or customzied | |||

-

APMA Drilling Mud Agitator

-

Specifications

| Model | APMA5.5 | APMA7.5 | APMA11 | APMA15 |

|---|---|---|---|---|

| Motor | 5.5KW | 7.5KW | 11KW | 15KW |

| Impeller Speed | 60172RPM | 60172RPM | 60172RPM | 60172RPM |

| Single Impeller | 850mm | 950mm | 1050mm | 1200mm |

| Dual Impeller | N/A | Up:800mm | Up:850mm | Up:950mm |

| Dual Impeller | N/A | Down:800mm | Down:850mm | Down:950mm |

| Ratio | 25:1 | 25:1 | 25:1 | 25:1 |

| Shaft Length | Depends on tank depth | |||

| Power System | 380V/50HZ,460V/60HZ (Customer built} | |||

| Remark | Explosion proof motor is available, shaft stabilizer is available | |||

-

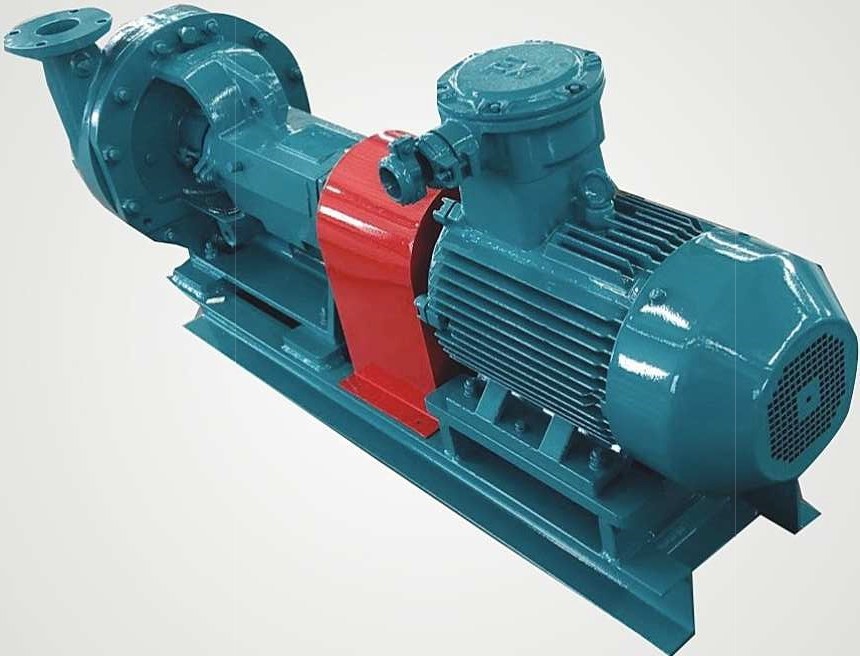

APSB Centrifugal Pump

-

Specifications

| Model | Flow Rate | Head | Power | Speed | Efficiency |

|---|---|---|---|---|---|

| APSB8x6-14 | 255m3/h | 32m | 75KW | 1450RPM | 67% |

| APSB8x6-14 | 240m3/h | 24m | 55KW | 1450RPM | 63% |

| APSB8x6-11 | 220m3/h | 23m | 45KW | 1450RPM | 65% |

| APSB6x5-14 | 190m3/h | 24m | 37KW | 1450RPM | 70% |

| APSB5x4-14 | 120m3/h | 30m | 30KW | 1450RPM | 68% |

| APSB4x3-13 | 80m3/h | 22m | 15KW | 1450RPM | 65% |

| APSB3x2-13 | 50m3/h | 25m | 11KW | 1450RPM | 55% |

-

APJQB Shear Pump

-

Specifications

| Model | Flow Rate | Head | Power | Speed | Efficiency |

|---|---|---|---|---|---|

| APJQB6545 | 155m3/h | 35m | 55KW | 980KG | 1150x1100x1500mm |

| APJQB6535 | 100m3/h | 24M | 37KW | 800KG | 1150x1100x1250mm |

-

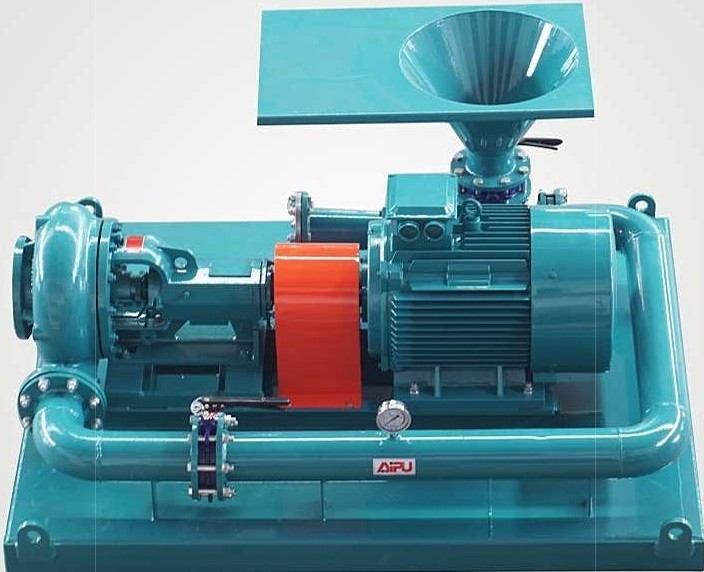

APSLH Jet Mud Mixer

-

Specifications

| Model | APSLH150-50 | APSLH150-40 | APSLH150-35 |

|---|---|---|---|

| C-Pump | SB8x6-13 | SB6x5-13 | SB5x4-13 |

| Capacity(m'/h) | 240m3/h | 200m3/h | 90m3/h |

| Head(m) | 40m | 35m | 40m |

| Power(kw) | 55Kw | 45m | 30m |

| Inlet Dia. | 200mm | 150mm | 125mm |

| Nozzle Dia. | 50mm | 40mm | 35mm |

| Compounding Density | ≤1.8g/cm3 | ≤1.6g/cm3 | ≤1.8g/cm3 |

| Compounding Viscosity | ≤120s | ≤120s | ≤120s |

-

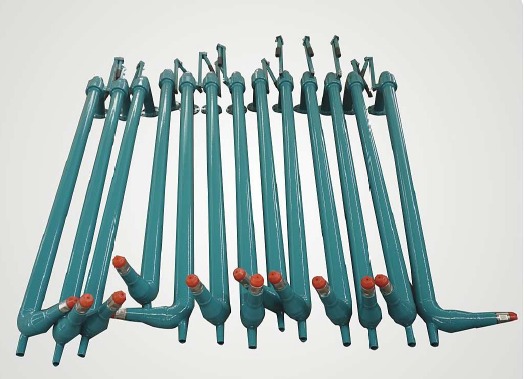

APNJQ Mud Gun

-

Specifications

| Model | Diameter (mm) | Pressure | Nozzle | Rotation |

|---|---|---|---|---|

| APNJQ50 | 50mm/2in | Customizable | 1 or 3 | 0~360 |

| APNJQ80 | 80mm/2in | Customizable | 1 or 3 | 0~360 |

-

APMGS Mud Gas Separator

-

Specifications

| Model | APMGS800 | APMGS1000 | APMGS1200 |

|---|---|---|---|

| Vessel Dia. | 800mm | 1000mm | 1200mm |

| Flow Rate | 200~260m3/h | 240~300m3/h | 280~360m3/h |

| Inlet Dia. | 5" | 5" | 5" |

| Discharge Line Dia. | 8" | 8" | 10" |

| Vent Line | 8" | 8" | 8" |

| Pressure | customizable | ||

-

APVCD Cuttings Dryer

-

Specifications

| Model | APVCD900 | APVCD?O0 |

|---|---|---|

| capacity | 30~50t/h | 20~40t/h |

| Drying efficiency | < 5% | < 5% |

| Screen Dia | Ჶ900 | Ჶ700 |

| Screen Opening | 0.25~0.5 | 0.25~0.5 |

| Rotation Speed | 900RPM | 900RPM |

| Separation Factor | 408G | 408G |

| Main Motor | 55KW | 22KW |

| Oil Pump Motor | 0.55KW | 0.37KW |

-

APMC Mud Cleaning System

-

Specifications

| Model | Capacity | Separation Size | Water Content of Discharge | Power |

|---|---|---|---|---|

| APMC50 | 50m3/h | 30 µ m | < 50% | 18KW |

| APMC100 | 100m3/h | 30 µ m | < 50% | 22KW |

| APMC200 | 200m3/h | 60 µ m | < 50% | 50KW |

| APMC250 | 250m3/h | 60 µ m | < 50% | 60KW |

| APMC500 | 500m3/h | 60 µ m | < 50% | 145KW |